You can alter the positions of your hands on either side of the cheese to define complex and curved shapes. Imagine stretching a thin metal wire between your hands and sliding it though a block of cheese cutting any shape you want. Perhaps the best way to explain wire EDM is to use an analogy. The path of the wire is typically controlled by a computer, which allows extremely complex shapes to be produced. If you were to observe the wire EDM process under a microscope, you would discover that the wire itself does not actually touch the metal to be cut the electrical discharges actually remove small amounts of material and allow the wire to be moved through the workpiece. Wire EDM is usually performed in a bath of water. Special brass wires are typically used the wire is slowly fed through the material and the electrical discharges actually cut the workpiece. In wire EDM a very thin wire serves as the electrode. Serves as a coolant to minimize the heat affected zone (thereby preventing potential damage to the workpiece)Īcts as a conductor for the current to pass between the electrode and the workpiece.

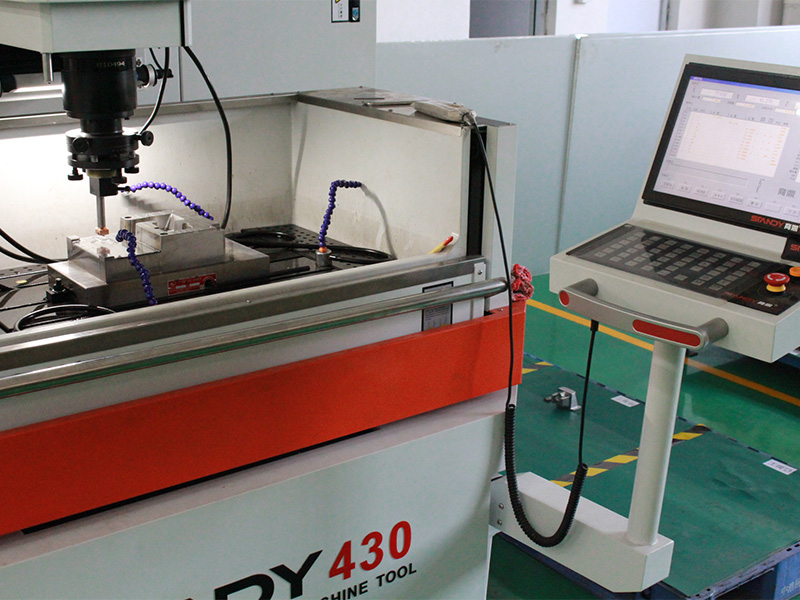

The fluid serves the following three purposes: The entire machining operation is usually performed while submerged in a fluid bath. The now specially-shaped electrode is connected to the power source, attached to a ram, and slowly fed into the workpiece. In a typical ram EDM application, a graphite electrode is machined with traditional tools. The primary difference between the two involves the electrode that is used to perform the machining. There are two primary EDM methods: ram EDM and wire EDM. The repetitive discharges create a set of successively deeper craters in the work piece until the final shape is produced. The small amount of material that is removed from the workpiece is flushed away with a continuously flowing fluid. These electrical discharges are passed between an electrode and the piece of metal being machined.

#EDM MACHINING SERIES#

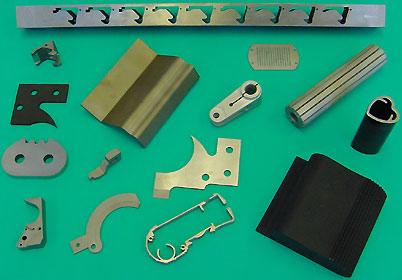

Metals that can be machined with EDM include hastalloy, hardened tool-steel, titanium, carbide, inconel and kovar.ĮDM is sometimes called “spark machining” because it removes metal by producing a rapid series of repetitive electrical discharges. EDM or Electrical Discharge Machining, is especially well-suited for cutting intricate contours or delicate cavities that would be difficult to produce with a grinder, an end mill or other cutting tools. One critical limitation, however, is that EDM only works with materials that are electrically conductive. Tricks of the Trade | What Is EDM Machining?ĮDM is a machining method primarily used for hard metals or those that would be impossible to machine with traditional techniques.

0 kommentar(er)

0 kommentar(er)